iSurface at JEC World 2026 | Paris | March 10 - 12

Intelligence, built into the material.

A new class of composite materials that sense impact, load and damage as they occur, enabling real-time structural awareness beyond inspection.

STRUCTURAL AWARENESS BEYOND INSPECTION

Intelligent composites.

Built to sense what inspection can’t

At JEC World 2026 in Paris, iSurface presents a new approach to structural awareness in advanced composite materials.

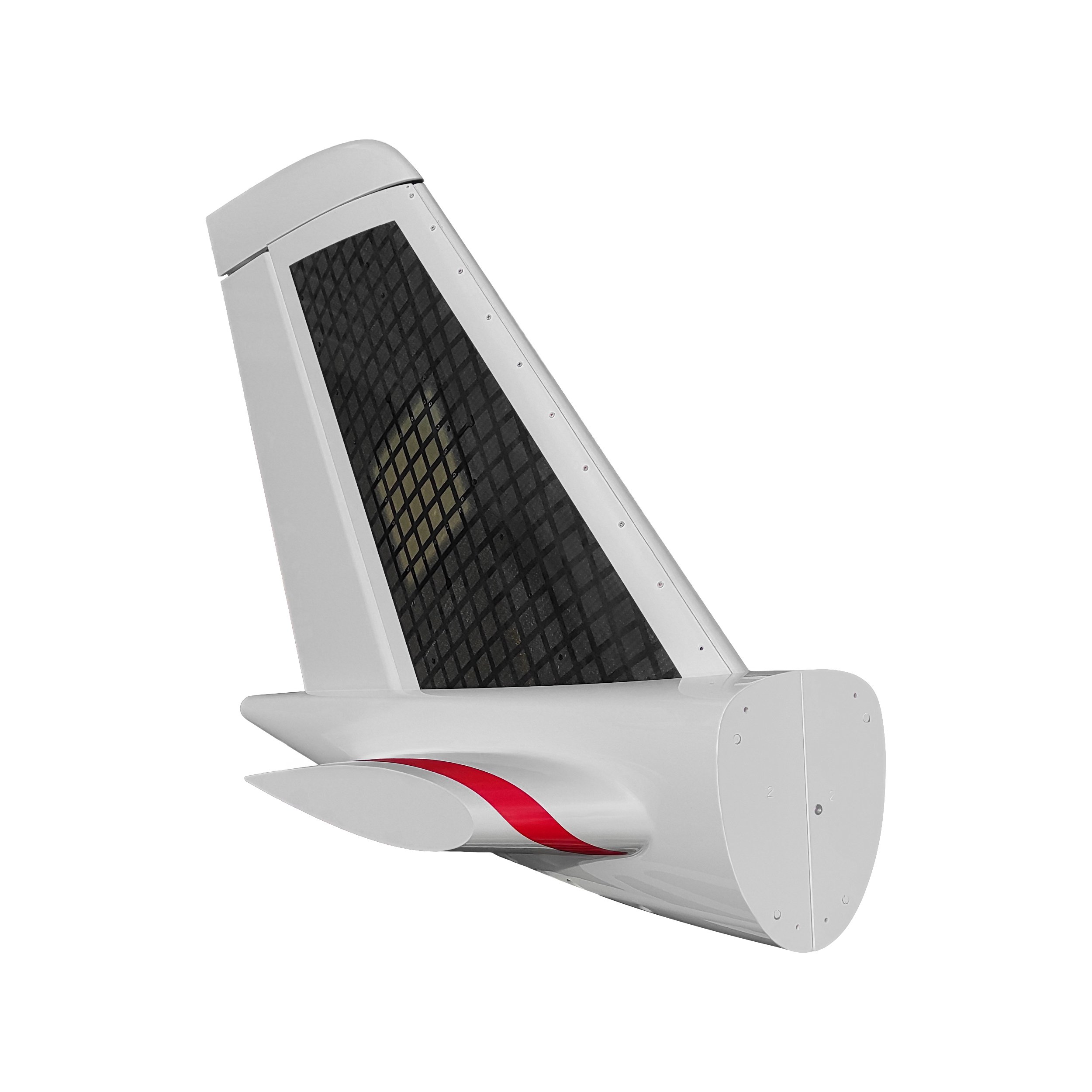

By embedding sensing capability directly within the laminate, iSurface enables real time insight into impact events, loading and damage evolution, including barely visible impact damage that traditional inspection methods struggle to detect.

Developed through a collaboration between materials science, aerospace engineering and AI-driven diagnostics, iSurface transforms composite structures from passive components into active systems.

The result is a pathway toward condition based maintenance, improved reliability and a deeper understanding of how structures behave in real operating environments across aerospace, energy and high performance applications.

iSurface Partners

Where iSurface Fits

From aerospace to energy and advanced mobility, iSurface enables condition based decisions by sensing impact, load and damage as they occur. It provides structural context that traditional inspection cycles can’t capture in the moment, a practical step toward less downtime, fewer surprises and smarter part-life management.

Aerospace & Aviation

Where iSurface started: composites exposed to FOD/BVID, high inspection burden, and safety-critical uptime.

Wind energy

Persistent monitoring for composite blades to support condition based maintenance and reduce downtime.

Motorsport / high-performance vehicles

Understand impacts and fatigue on composite parts to support faster decisions and faster development cycles.

Advanced mobility

Detect and assess impact/fatigue in composite structures to reduce precautionary replacements and uncertainty.

Maritime & naval

Structural awareness for composite hulls/structures to improve safety assurance and reduce disruption.

Robotics & advanced manufacturing

Detect contact/deflection/anomalies in real time for precision systems and next-gen manufacturing.

Explore the Science Behind iSurface

Our whitepaper, "Intelligent Composites - Structural awareness beyond inspection", shares the data, testing, and results behind iSurface - including fracture-toughness uplift and real-time diagnostics. Available now for download.

Large-area sensing with built-in redundancy

A distributed sensor lattice maintains coverage if a local region is damaged, with signalling re-routed around the affected area. Integration pathways include co-cure, retrofit to the skin, or primer/paint-layer incorporation, minimising process change while enabling persistent monitoring.

Real-time awareness within the composite structures

iSurface embeds a thin, electrically conductive layer that generates clean signals during impact, strain, bending, and shear. AI-based modelling interprets these signals in real time to characterise events, locate affected regions, and support condition-based maintenance decisions.

Strength and intelligence, combined

Representative laminates demonstrated fracture-toughness uplift of up to +87% (Mode I) and +244% (Mode II) versus baseline, while enabling live sensing and AI-driven diagnostics.

This supports a shift from schedule-based inspection to data-driven, condition-based maintenance, reducing routine inspection burden and unplanned downtime.

Note: Performance varies by layup; results obtained under controlled testing to aerospace standards.

Meet iSurface at JEC World 2026

Share a few details and the team will follow up to arrange a time during JEC World.

© 2026 Munro Technology. All rights reserved.